Table of Contents

Key Takeaways

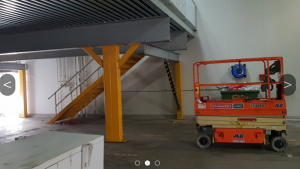

Mezzanine floor systems are elevated platforms that optimise overhead vertical space within warehouses, factories, and various facilities, offering a flexible solution for expanding business space or storage capacity. These systems can be tailored to meet the specific requirements of different industries, with the ability to be reconfigured or relocated as business needs evolve. Benefits include cost-effectiveness, increased floor space (up to double or triple the original), enhanced productivity due to closer proximity of resources, and quick installation times. Customised mezzanine floor systems can range from heavy-duty, high weight load floors to soundproof floors, food processing compliant floors, and even weather-resistant external floors, demonstrating the versatility and adaptability of mezzanine solutions to various operational needs.

What Are Mezzanine Floor Systems?

Mezzanine floor systems are elevated platforms that utilise the overhead, vertical space of a warehouse, factory, facility or distribution centre. They can sit above shelving or racking, and can be customised to suit a range of industries and needs. They are a great investment whether you want to expand your business or space in the long term or short term as they can be reconfigured if you plan to change your location.

Benefits of a warehouse mezzanine floor

Warehouse mezzanine floors are inexpensive for the return on investment and advantages that they offer.

-

- Versatility of mezzanines allow for easy reconfiguration and relocation

-

- Increases floor space up to twice or triple the size of your current warehouse. Mezzanines also maximises storage and unused overhead room

-

- Saves relocation and construction costs

-

- Reduces disruptions and interference to the business operations that relocating can cause

-

- Cost effective and will increase ROI by allowing you to expand your business

-

- Heavy duty, durable structures that will last and endure harsh conditions

-

- Increases productivity by having everything you need in close proximity

-

- Installed within a short period of time

-

- Can be customised to suit your specific business needs

Customised Mezzanine Floor Systems

We have provided a list of 7 customised mezzanine warehouse floor system examples for any business from Brisbane to Melbourne. Based on our experience and previous projects we have illustrated options available for your warehouse needs. Not every application is suitable for a standard mezzanine and will require a customised mezzanine floor design to suit specific applications. Below are 7 different customised floors. 1 of these designs may better suit your needs.

Heavy Duty High Weight Load Mezzanine Floors

Customised High Weight Load Mezzanine Floor

High weight capacity mezzanine floors are floors designed to hold more weight than the typical industry standard of 300 kg per square metre. This mezzanine floor design therefore allows for more storage capabilities. A floor over 300 kg/m2 is considered a customised mezzanine floor.

The weight capacity of a mezzanine floor can be more than 1 tonne per square metre.

The typical weight capacity increments for a high weight capacity floor are:

- 500kg/m2

- 700kg/m2

- 1000kg/m2

Extra-High Lift Mezzanine Floors

Customised High Lift Mezzanine Floor

In some circumstances, particularly in the automation logistics industry, unusually high mezzanine floors are required to incorporate with robotic automation systems for the logistics industry.

Extra high mezzanine floors are engineered with additional bracing and heavy-duty steel to withstand the increased forces and tension. Additionally, customised staircases are necessary.

Food Processing Compliant Mezzanine Floors

Customised Food Processing Compliant Mezzanine Floor

Food Processing Mezzanine Floors must be built to meet the stringent food processing requirements.

This involves selective floor material and compliant structural material.

Soundproof Mezzanine Floors

Soundproof Mezzanine Floors are often utilised in circumstances where high noise machinery is used above the floor, or underneath. Also, in commercial office environments or functions centres where noise must be suppressed.

A sound-proof mezzanine floor utilises either a concrete floor or aerated concrete floor product.

A recent example is the Avionics project.

Integrated Machinery Mezzanine Floors

Customised Integrated Machinery Mezzanine Floor

Often machinery requires platforms or a raised floor to be integrated with equipment for improved production efficiency. This allows better access to the equipment and a safer working environment. Customised mezzanine floors can be built to incorporate the machinery and facilitate the machines ancillary upstream or downstream requirements.

Gantry Crane Mezzanine Floors

Customised Mezzanine Floor – Gantry Crane Mezzanine Floor

Gantry crane mezzanine floors are useful in a manufacturing setting. Often where the height is available the floor can double as storage and a gantry crane structure. Particularly useful where there is no existing gantry crane structure in the building or the factory Is being leased and you have the option to dismantle the gantry mezzanine floor and move it with you throughout the life of the business.

External (weather resistant) Mezzanine Floors

Customised Mezzanine Floor – External (weather resistant) Mezzanine Floor

In some circumstances, a mezzanine floor built outside of the factory is a great way of optimising the space above your carpark or office to increase storage. The outside mezzanine floor is built using weather-resistant materials such as galvanised steel and compressed fibro concrete sheet to withstand the elements.

Mezzanine floor systems: racking, longspan and structural

Racking mezzanine floor system

The rack-supported mezzanine floor system uses pallet racking materials and is built as a freestanding structure that is not supported by any existing part of your building. This mezzanine storage platform is constructed with pallet racking frames and beams, where the beams are hooked straight onto the floor posts, and safely secured with locking pins. The mezzanine floor can be placed above or in between pallet racking bays. Racking based mezzanine storage systems can be easily reconfigured, extended and relocated if needed.

Longspan mezzanine floor system

The longspan mezzanine floor is ideal for businesses that store small parts. This can include those who need to store mining equipment, automotive parts, electrical goods and archive materials. As small goods require manual handling, It utilises longspan shelving for a non-palletised storage system. Mezzanine’s are a cost effective choice for those who want to maximise their storage. Particle board, mesh or steel flooring is used in the longspan mezzanine system.

Structural/clear span mezzanine floor system

The structural mezzanine system is perfect for heavy duty storage. Made to withstand large loads, they are built with structural steel posts and beams. For better accessibility, this system normally has wide column spans. This system is usually chosen for retail and office use, or constructed on top of existing storage and work areas.

Process of warehouse mezzanine floor construction

The Heighton Mezzanines’ process of mezzanine floor system construction is as follows:

Site inspection – we consult with you on every feature of the mezzanine design, and measure the space to ensure we fully understand your requirements.

Design – our specialists draw up a design that meets your budget and is compliant to safety standards.

Manufacturing – once approved, we produce the materials in Australia using locally sourced quality materials.

Installation – we construct the mezzanine floor in your warehouse or facility, with little interference to your business operations.

Custom designed warehouse mezzanines

There are endless configurations that you can choose from when it comes to warehouse mezzanines. The main factor you need to consider is the purpose of your mezzanine floor and the weight capacity required. Whether you want to install mezzanine storage, offices or cleanrooms there will be a range of different design aspects that will differ in each structure. Heighton Mezzanines will recommend the right design, materials, access and floor size based on your business requirements. The customisable features include:

-

- Timber, concrete or steel flooring

-

- Pallet gates

-

- Stair case

-

- Hand rail

-

- Mezzanine floor area

-

- Floor height

-

- Column spacing

-

- Weight capacity

-

- Number of tiers

-

- Shelving

If you’re not sure where to begin, speak with the experts and we can create a design that will best capture your needs.

Industry applications of mezzanine floor systems

Warehouse mezzanine solutions can be created for all sorts of business from any industry. Whether you carry small goods or bulkier items, you can find mezzanine storage shelving and floor structures that are tailored to your operational needs. These can include business that offer:

-

- Small parts manufacturing

-

- Medical equipment

-

- Electronics

-

- Furniture

-

- Farming equipment

-

- Bedding

-

- Retail and wholesale products

-

- Machinery

-

- Construction materials

-

- Irrigation

-

- Hydraulic equipment

-

- Hardware

-

- Automotive goods

-

- Logistics and supply

Some businesses may even choose to integrate long span shelving with the mezzanine racking system for added storage. There are no limits to what you can do with a mezzanine floor, and by working with the right professionals, we can help you design the best solution for your requirements.

Warehouse mezzanine floor installation

The Heighton Mezzanines team of specialists have been expertly trained and licensed to construct mezzanine floors. With years of experience, we’ve delivered countless mezzanine solutions for our customers. We are fully compliant with the Australian standards for all our mezzanine floor construction projects. So you can trust us with designing and installing a quality mezzanine that will serve its purpose and surpass your expectations. We offer our mezzanine products and installation services all across Australia, so your business can easily benefit from a warehouse mezzanine floor whether you’re in Brisbane, Perth of Sydney.

Industrial mezzanine staircases

Whether your mezzanine floor system is for an office space, storage or something totally different, you will need a staircase to provide access to your staff. If you need a way to transport goods between ground level and the mezzanine floors, we can also include that in your design. We offer various mezzanine staircase designs and railings that you can customise to fit your workspace.

FAQs

What is a mezzanine floor system?

A mezzanine floor system is a floor structure that is commonly installed in warehouses, facilities, distribution centres or buildings in order to expand the space. It takes advantage of the unused vertical space in a building to double or triple the available available room. Mezzanine floor systems can be used for storage space, offices, cleanrooms and more.

What is mezzanine storage?

Mezzanine storage refers to installing a mezzanine platform for the purpose of increasing space for storing goods. Businesses can choose between a rack-supported mezzanine or longspan mezzanine floor system depending on whether they store small parts or heavy duty goods. Longspan mezzanine shelving is ideal for small, manually handled parts.

What is the minimum height for a mezzanine floor?

The minimum height requirement for a mezzanine floor is 2.1m from the ground level. Mezzanine floor systems can only be built in buildings that have a ceiling height of 4.4 m. These regulations are set out by the Australian Building Regulation standards. This also applies to every additional tier you add to the mezzanine structure.

How much weight can a mezzanine floor system hold?

Mezzanine floor systems can be designed to withstand light or heavy loads. A general mezzanine floor should be able to endure up to 300kg per square metre but can be built to hold in excess of 1 tonne per square metre. Depending on your business’ purpose and load requirements, the mezzanine can be designed with the right materials to bear the intended weight capacities.

What material is used for mezzanine flooring systems?

There are various materials that can be used in the construction of mezzanine floors including timber, structural ply, concrete, metal mesh or chipboard. For the uprights, bearers and joists, galvanised steel is used for strength and durability. You can choose your floor decking material based on what kind of traffic you expect, use of trolleys, machinery, as well as chemical use.

Does a mezzanine floor count as a storey?

Yes, a mezzanine can count as a storey depending on its floor area, it has to be more than 200m2 or more than one third of the floor area of the room, the lesser of the two. Two or more mezzanines are considered a storey if they are near the same level or at the same level; and have a total floor area of more than 200m2 or more than a third of the room’s floor area, whichever is less.

Do I need a permit to build a mezzanine?

There may be some situations where you will require a permit to build a mezzanine. Local council planning permits may be needed if you are building a mezzanine that is used for work purposes, such as an office or working area. Another reason you might need a permit is if you plan to attach the mezzanine to another pre-existing wall or structure. Mezzanine storage generally does not require a permit.

How much does a warehouse mezzanine cost?

The price of a warehouse mezzanine considers various aspects such as the floor size, materials used, weight capacity, other additional features as well as your location. The complexity of an installation is also another factor that determines the price, an easily accessible area makes the overall price cheaper than if there is a production site below, and if there is food that can be contaminated.

What is the difference between a loft and a mezzanine?

The difference between a loft and a mezzanine is in their structure. A loft is usually an open plan area directly below a roof, and accessible by ladder. It is commonly found in a home or apartment, and can sometimes be used for storage, or as a lounge or bedroom area. A mezzanine is more of an intermediate, open space floor that can be constructed in a home for extra living space or bedrooms. Mezzanine floor systems can also be installed in restaurants, shopping centres and industrial buildings for additional storage, offices or working space.

How do you build a mezzanine floor?

A mezzanine floor system is built with mezzanine floor posts (uprights), main beams (bearers), secondary cross beams (joists), the decking, a staircase and a gate. There are various mezzanine floor designs and configurations depending on your specifications. The construction process involves connecting the uprights to the bearers, and then the joists are attached in between the main bearers. Lastly the decking is constructed with additional balustrading, gates and staircases. Mezzanine installation must comply with the Australian safety standards.

No Obligation Consultation -

Your Questions,

Our Expertise

Why Chat With Us?

We understand the importance of making informed decisions. This is why we offer a no-obligation consultation with our specialist consultants. Our team of experts consultants is not just knowledgeable; they are passionate about providing bespoke solutions that fit your unique needs.